Construction of overhead cranes

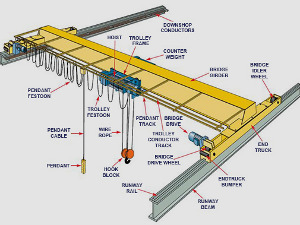

Among the construction elements, mechanical and electrical ones are distinguished. If you choose crane course, then all the precise information about the construction of the device is given during the class. Below is a schematic representation of the crane construction.

Mechanical elements:

- on the track - cams and buffers

- the steel structure of the equipment, i.e. the front end - driving mechanism, driving and travel wheel, buffers, stopping claws, limit switches, wind protection and copper brushes

- the bridge, usually an I-beam, which is responsible for the path of the bogie and contains the buffers

- driving bogie - made up of a motor and a toothed gearbox

- lifting mechanism - body, wire rope, drive motor, geared transmission, chain or rope drum with grooves, rope guide ring, ropes with buffers and limit switch, hook block and hook

Electrical components:

- crane switch - responsible for switching the power off and on with the power circuit

- power switch - responsible for switching the crane's power on and off, usually installed on the platform

- trolleys - current collectors

- control and distribution cabinets

- installation switchboxes on the bridge

- control pendant

- limit switches

All components are responsible for three basic movements: these are the movements of the platform, the movements of the linkage and the lifting movements of the sling on which the load is placed. This makes it easier to carry out transport on the work site, including larger and heavier loads.

Depending on the type of crane, individual structural components are also distinguished.

Building a gateway model:

Gantries use a platform that is suspended from side bridges that are the link for two or more gates. The gantries have wheeled or rail-mounted chassis. The gantry piers are traversed by tendons.

Building a bridging model:

The bridge models use a trussed rolling deck with rails that are mounted against the ceiling of the room. A tendon moves along the platform thus constructed.

Depending on the model, the equipment can be operated from the pavement by wired or wireless control, or can be fitted with an operator's cab. Most commonly, larger units have cabs, while smaller units can be operated remotely.

Any person wishing to obtain entitlements on cranes, should be thoroughly familiar with their construction. Knowledge of the construction is fundamental in the safe operation of the equipment, which translates into a reduced risk of accidents at work. The information given during training is crucial in this case, so as a future operator of the equipment, it is important to be thoroughly familiar with its operating principles and individual components.