Preparatory activities

Activities before working with the crane

Activities before working with the crane

The most effective way to reduce the risk of hazards, including accidents, when operating overhead cranes is to have a precise knowledge of and adhere to health and safety rules. These activities must be carried out both before, during and after operating the equipment. The following are the necessary steps before starting work.

Before starting work, each equipment operator is mainly required to carry out special inspection work. Their purpose is to ensure that both themselves and the other workers are safe at their stations. The following activities are taught to everyone crane course, so the person should know how to proceed afterwards.

The most important rules before working with cranes:

- work on the equipment may only be carried out if it has a valid decision issued by the Office of Technical Inspection

- the operator must observe all regulations at all times when operating the equipment Health and Safetyincluding the work instructions and, in addition, the instructions for operating the equipment

- work with the tool may only be carried out by a person who has the appropriate entitlements for cranes

- in the event of defects, stop operation immediately, immobilise the equipment and inform the person responsible

Actions that must be taken before starting work:

refer to the current information in the operating manual, maintenance book or commissioning book for the relevant equipment

- check that the appliance is in a safe position and that there are no dangerous objects or persons in the vicinity of the appliance

- carefully check all the weights of the loads to be moved and compare them with the maximum capacity of the equipment, in order not to exceed the limit

- communication signs must be agreed with the hook operator

- prepare the storage area properly

- carry out an inspection of the equipment - this is an important point that must be carried out each time before starting work

An overview of the device consists of:

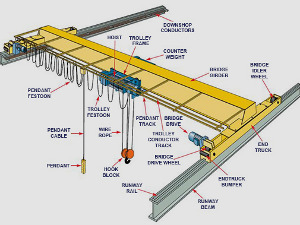

- visual functional check - check the working environment, the running gear, the condition of the equipment and individual components, e.g. for mechanical damage or leaks; also check the running gear of the hoist or winch and the bridge, the rope, the load chain, the gripping device, the safety guards. In addition, check that the equipment is not blocked, out of service or currently undergoing maintenance or inspection.

- checking the individual safety components - checking the operability of the main switch, the cassette control, the warning mechanisms, the movement locking devices, the control devices, the "STOP" switch, the end switches, the load brake and the lift limiter and slipping clutch also with the equipment. In addition, the operator must check that the equipment moves in accordance with the markings on the control panel

- check the efficiency of the drive mechanisms - a test run of the machine is required

Finally, the completion of the work should be marked in the operations book.

Activities before working with the crane

Activities before working with the crane